InfinityLine V+

Vertical processing with clamping frames

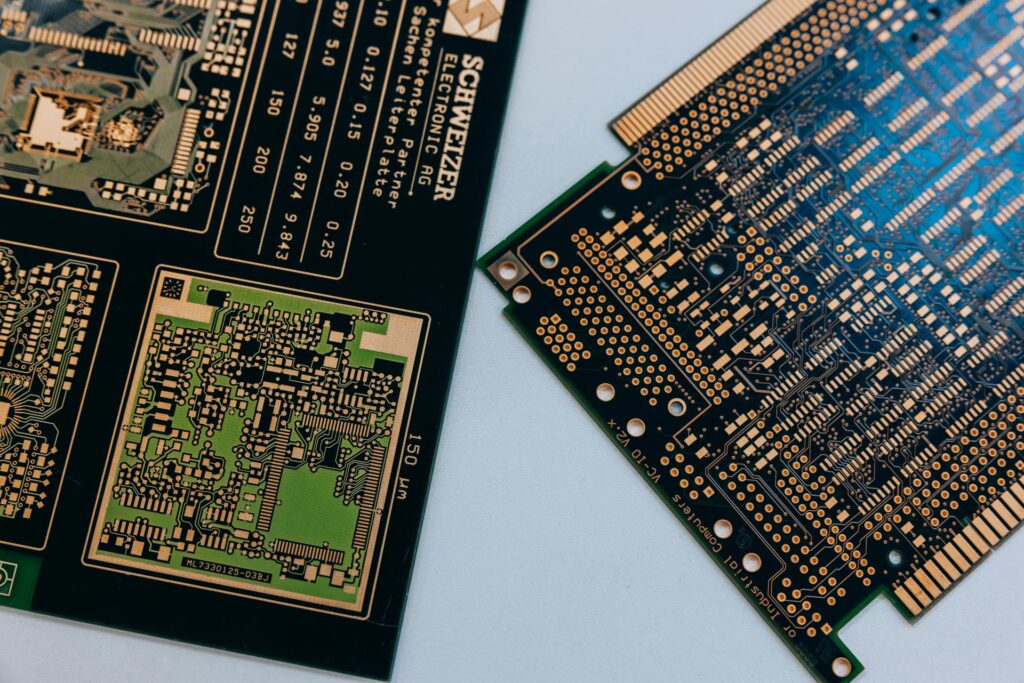

The vertical processing of printed circuit boards and substrates using transport clamping frames opens up new possibilities. Not only the contactless transport, but also the absolutely homogeneous treatment characterizes this machine type. Most different wet-chemical processes can be implemented and easily integrated.

Details

Our new product series InfinityLine V+ provides the answer to the questions of future-oriented technologies such as SAP and mSAP in serial production for the Advanced HDI and IC substrate markets. The InfinityLine V+ is characterized by a vertical contact-less transport with innovative clamping frames.

The design allows to transport the thinnest substrates safely. The newly designed drive system, below the production level enables cleanroom capabilities in circuit board production is unrivaled to this day. Basis for this is the unique modular concept continually developed by SCHMID over decades. The InfinityLine V+ provides maximum flexibility and security of investment for all innovative processes.

Already today the InfinityLine V+ supports all requirements of the Industry 4.0 by providing interfaces to customer‘s individual manufacturing execution system (MES). It meets all industrial standards worldwide. Furthermore it has an option for mature 6GEM interfaces.

The web-enabled server interface offers the possibility to monitor and control the system by means of various mobile terminals.

Technical data

Panel sizes/dimensions:

- Thickness: 0.025 mm – 2.4 mm

- Minimum size: 18” x 18” (457 x 457 mm)

- Maximum size: 24” x 24” (610 x 610 mm)

- Use of transport clamping frames

Transport:

- Throughput: 4 panels per minute

- Transport speed: 0.2 – 6 m/min

Automation:

- Possibility for integration into an intra-logistic system (SCHMID single panel / frame automation)

- Separate availiabillity for most different loader and unloader concepts

- User-oriented interfaces are configurable

Processes:

- Developing (Litho & SR)

- Flash-Etching

- Stripping (i.a. amines)

- Pre-Treating

- Ti-Etching

Contact

We look forward to meeting you!

Just choose your region and leave us a message.

EUROPE

CHINA

Tracy Xie

xie.tr@schmid-group.com

TAIWAN

Johnny Tseng

tseng.jo@schmid-group.com

KOREA

Jaho Kim

kim.jh@schmid-group.com

REST OF ASIA

AMERICA