Modular production concepts for multiple end process technologies

As a technology leader SCHMID supplies highly efficient equipment for the total value chain of photovoltaics. The product range includes single equipment for wafer, cell and module production as well as turnkey production lines and complete factory solutions. Thin-film manufacturers also place their trust in SCHMID’s technological expertise.

PERC

TOPCoRE

10.000 wph M12

TOPCon

IBC

Modular System Design

Wafers down to 50µm thickness

AGTex

Surface finishing for glass

The AGTex offers innovative methods for processing and finishing glass surfaces. The technology is particularly suited for the production of glasses with anti-glare properties.

Alkaline Texturing

Efficient texturing of mono-crystalline wafers

The Alkaline Texturing Inline System of SCHMID ensures the most efficient texturing of mono-crystalline wafers.

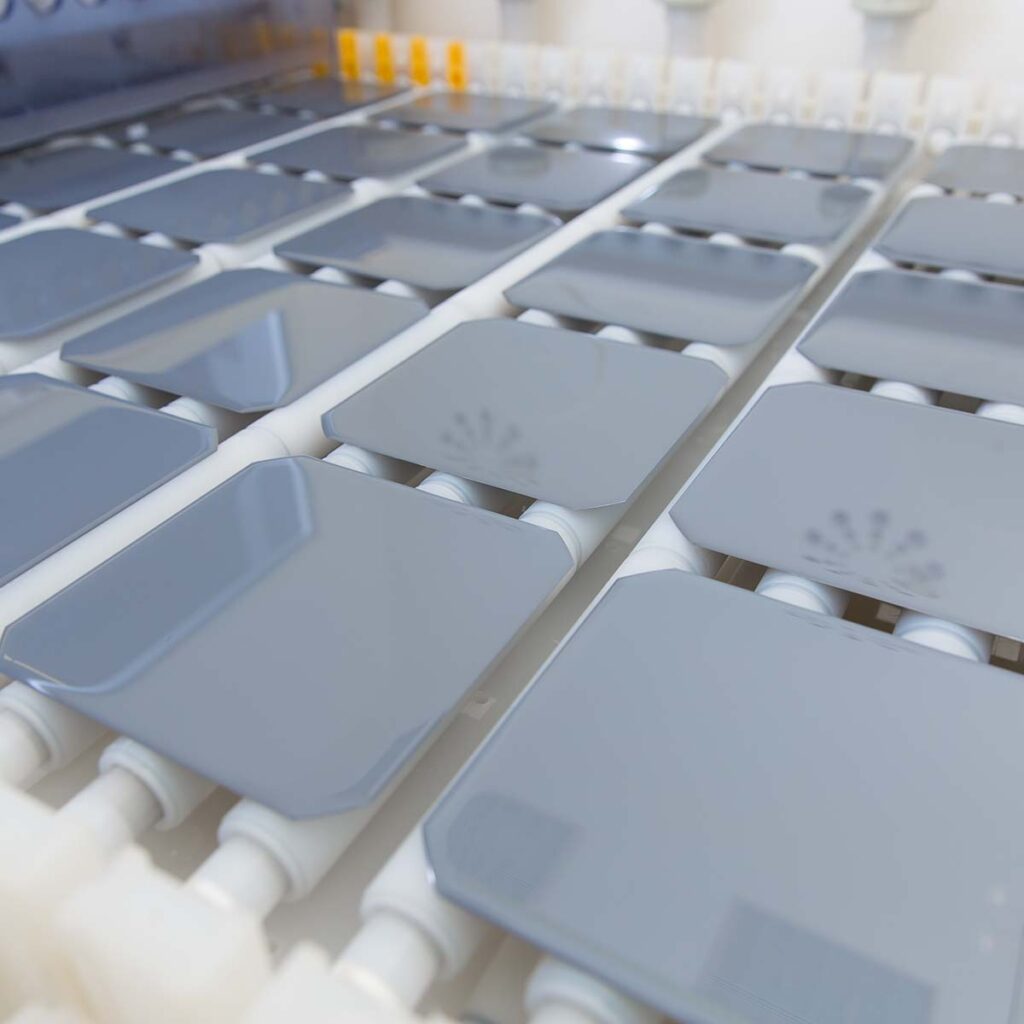

APCVD System

Low cost inline deposition of thin films

The 5500 series APCVD system is well suited for low cost high-volume processing for all cell architectures requiring single or multi-layer dielectric thin film deposition.

Edge Isolation & PSG Etching

Single-sided edge isolation for maximum efficiency

The Edge Isolation + PSG Etching Inline System fully automatically achieves a perfect edge isolation. In combination with the patented water mask the emitter is optimally isolated.

Poly Silicon & BSG Etching

Poly Silicon & BSG Etch for TOPCon Manufacturing

The Alkaline Poly–Si and BSG Etching Inline System achieves a perfect cleaning of the sunny side for n- and p-doped polysilicon and Boron glass removal.

Alkaline Polishing for PERC and TOPCon

NOX-free edge isolation and polishing

The single side alkaline polishing system achieves a perfectly polished and clean rear side for optimal cell performance.

Other markets

Electronics

Customer Service

Contact

We look forward to meeting you!

Just choose your region and leave us a message.

CHINA

Tracy Xie

xie.tr@schmid-group.com

TAIWAN

Johnny Tseng

tseng.jo@schmid-group.com

KOREA

Jaho Kim

kim.jh@schmid-group.com

REST OF ASIA

AMERICA