We keep your equipment state of the art

More than 60 service technicians spread over 7 service locations worldwide guarantee fast and comprehensive services to our customers. The Customer Service offers maintenance contracts, after sales, customer training as well as on-site services. Spare parts and logistics are also part of their service portfolio, as are modernizations that keep your machines up-to-date and cost-efficient.

Our service portfolio

Global, efficient & fast

Technical Support / Field Service

SCHMID offers worldwide and customer-oriented service with highly qualified service personnel available on four continents for remote maintenance and diagnosis.

Spare & Wear Parts

SCHMID has around 60,000 different items in stock to ensure fast and reliable shipping of spare parts to meet customer’s demands.

Modernization & Upgrades

Performance Auditing

Only with efficient production processes and a high level of machine availability your performance capabilities are completely up to date to put you at a competitive advantage. With a performance audit of today‘s requirements, we can show you what potential for improvement is available in your machine.

Modification

Thanks to our extensive possibilities for modifying your machine, you can effectively react to changes in your product and customer requirements, without having to invest too soon in new machinery.

Function Enhancement

Together with our experienced team you can develop ideas for upgrading your machine to improve its performance.

By installing additional modules and components or by applying new control and automation technologies functions can be considerably expanded.

Contact

We look forward to meeting you!

Just choose your region and call us or leave us a message.

EUROPE

CHINA

Tracy Xie

xie.tr@schmid-group.com

TAIWAN

Johnny Tseng

tseng.jo@schmid-group.com

KOREA

Jaho Kim

kim.jh@schmid-group.com

REST OF ASIA

AMERICA

We are here to help

You have any questions about products, services or anything else? Just let us know. We try our best to help.

Other markets

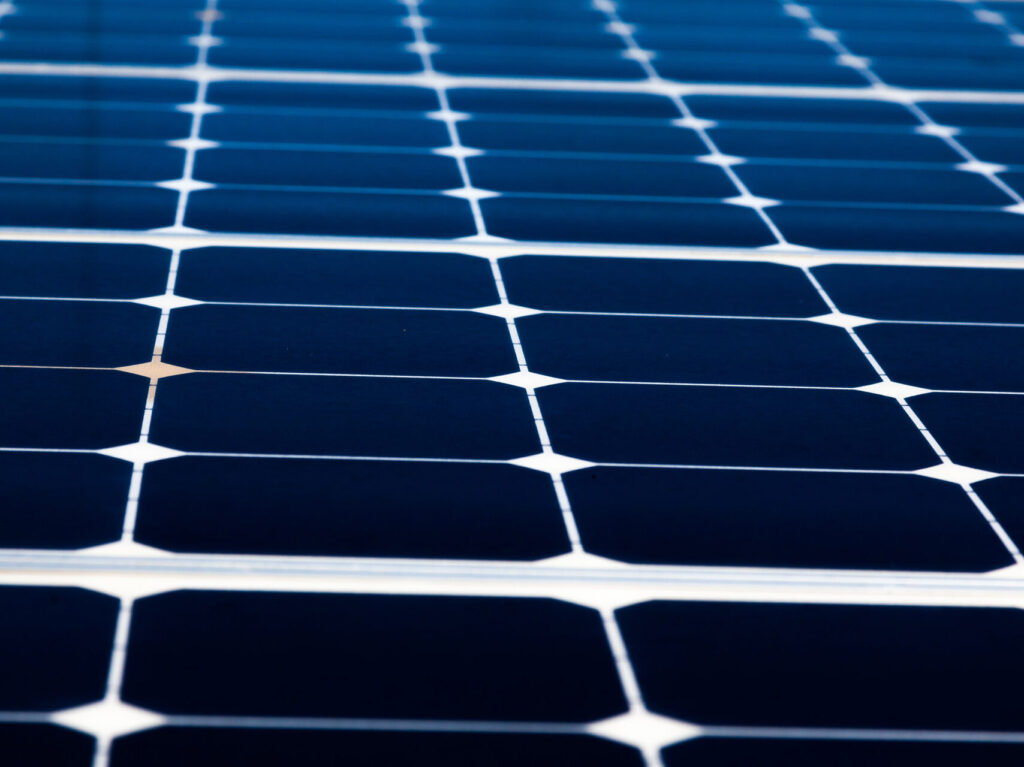

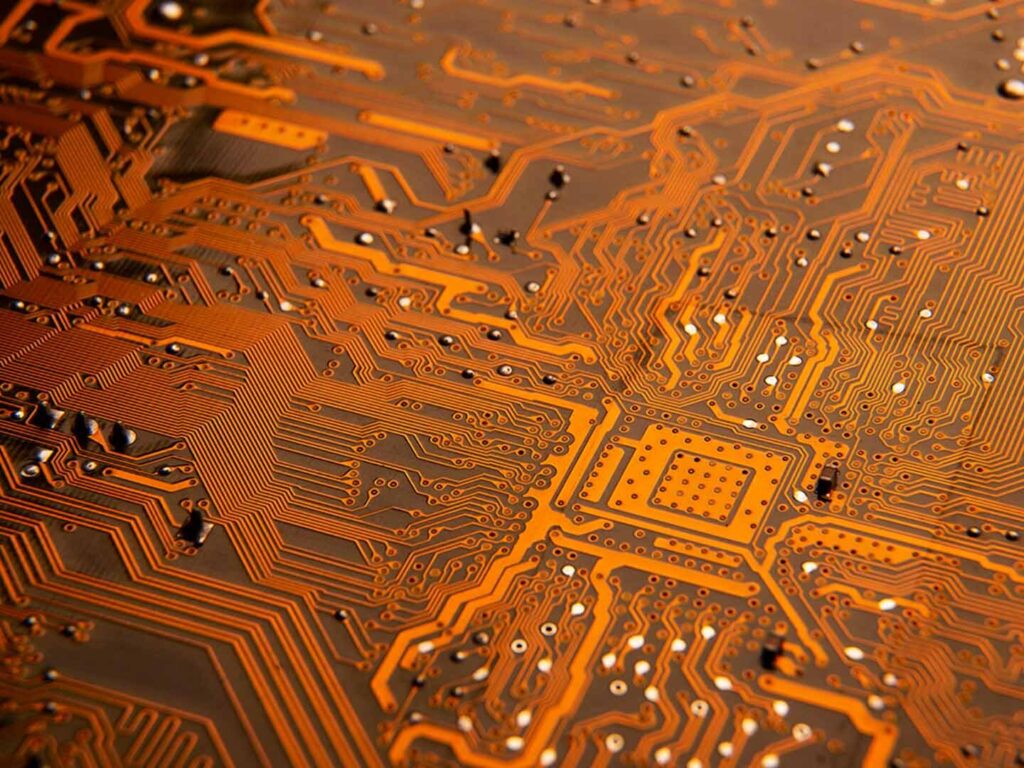

Electronics