Poly Silicon and BSG Etching

Poly Silicon and BSG Etch for TOPCon Manufacturing

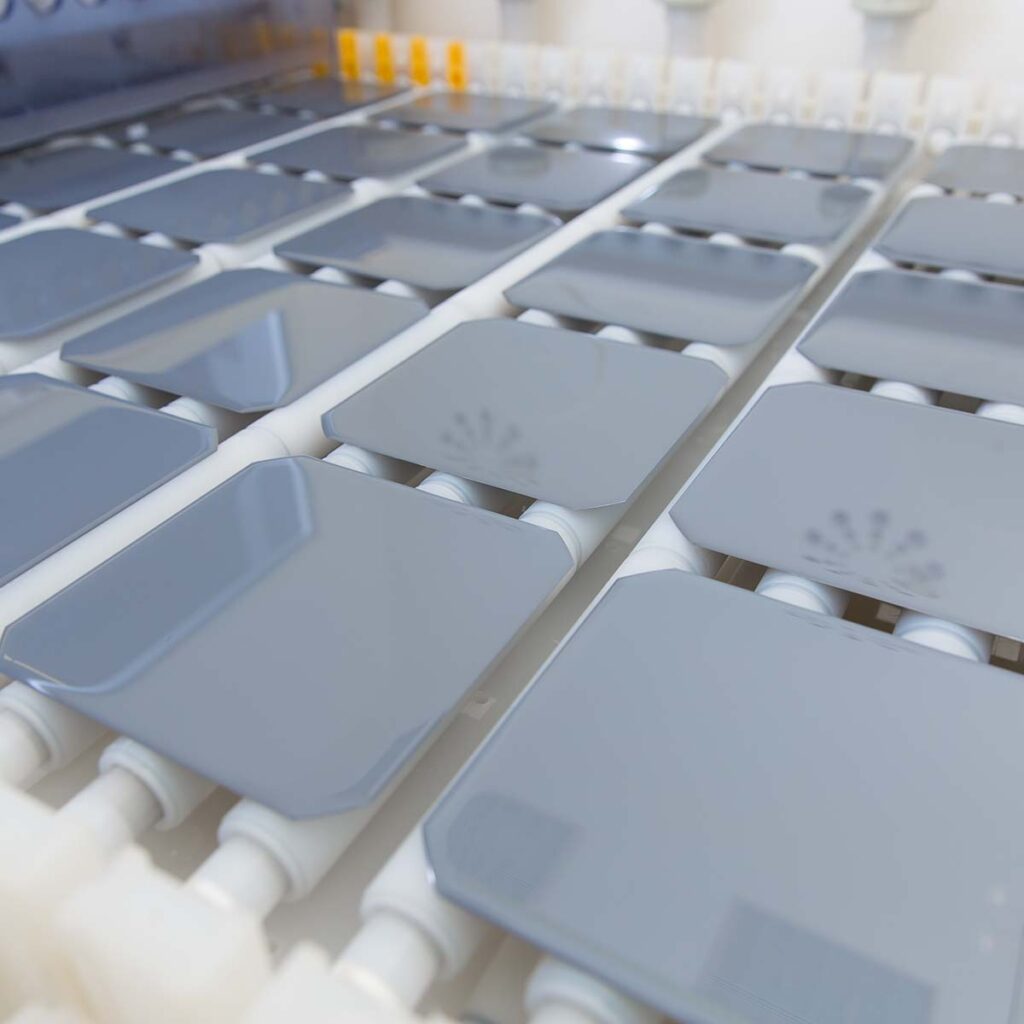

The Alkaline Poly–Si and BSG Etching Inline System achieves a perfect cleaning of the sunny side for n- and p-doped poly silicon and Borosilicate glass removal.

Details

The Alkaline Poly-Si and BSG Etching Inline System combines several process steps in a modular system. On the one hand the front side poly silicon warp around on the wafer generated during the Poly-Si process is unilaterally isolated from the front side of the wafer followed by a borosilicate or phosphorous glass removal.

With the Poly-Si and BSG Etching Inline System, SCHMID has a perfect solution for cleaning the front side of a TOPCon cell prior to passivation and antireflection coating in its portfolio with lowest chemical consumption.

Due to the inline concept an outstanding wafer to wafer uniformity is achieved along with the capability to process wafer thicknesses down to 100μm. In addition, processing at about 80 °C ensures a high etching rate and thus a small footprint of the system. During both the Poly-Si removal and doped glass removal the rear Poly-Si and tunnel oxide is protected by the water mask developed and patented by SCHMID.

Special transport rollers ensure that the chemistry comes into contact exclusively with the frontside, thus reducing the chemistry consumption. In addition, all processes are running in one system reducing the required number of systems, automation and avoids the usage of cassettes.

Other equipments for photovoltaics & glass

AGTex

Surface finishing for glass

The AGTex offers innovative methods for processing and finishing glass surfaces. The technology is particularly suitable for the production of antireflection and antiglare coatings on glass.

Alkaline Texturing

Efficient texturing of mono-crystalline wafers

The Alkaline Texturing Inline System of SCHMID ensures the most efficient texturing of mono-crystalline wafers.

APCVD System

Low cost inline deposition of thin films

The 5500 series APCVD system is well suited for low cost high-volume processing for all cell architectures requiring single or multi-layer dielectric thin film deposition.

Edge Isolation & PSG Etching

Single-sided edge isolation for maximum efficiency

The Edge Isolation + PSG Etching Inline System fully automatically achieves a perfect edge isolation. In combination with the patented water mask the emitter is optimally isolated.

Alkaline Polishing for PRTC and TOPCon

NOX-free edge isolation and polishing

The Alkaline Edge Isolation Inline System achieves a perfect edge isolation with an alkaline solution.

Contact

We look forward to getting to know you!

Simply select your region and leave us a message.

EUROPE

CHINA

Tracy Xie

xie.tr@schmid-group.com

TAIWAN

Johnny Tseng

tseng.jo@schmid-group.com

KOREA

Jaho Kim

kim.jh@schmid-group.com

REST OF ASIA

AMERICA