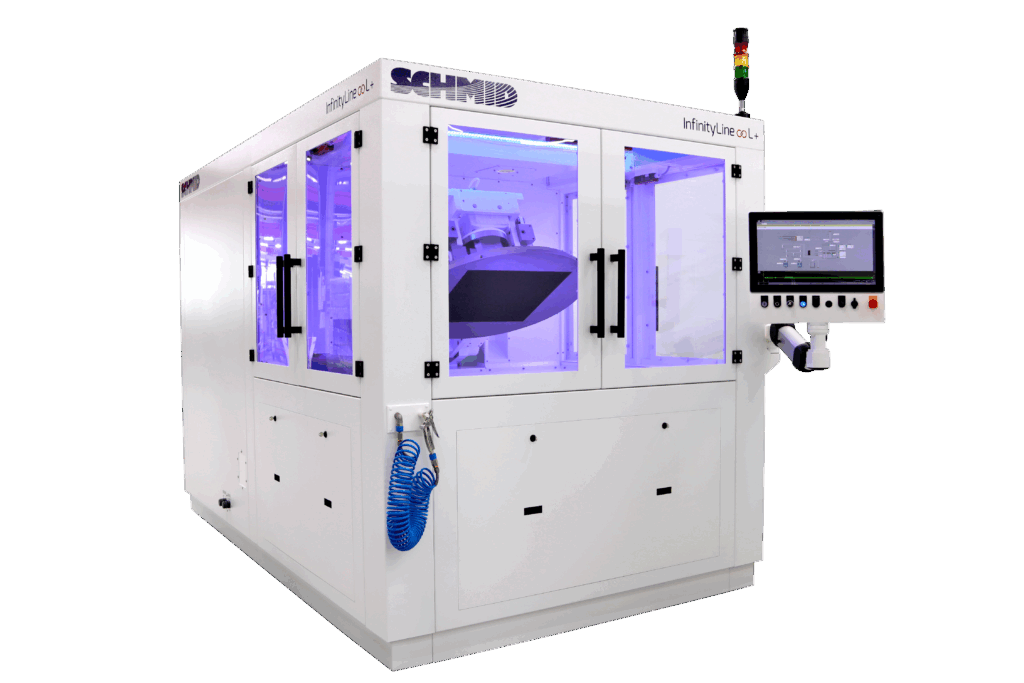

Chemical Mechanical Polishing by InfinityLine L+

Chemical Mechanical Planarization for rectangular substrates and PCBs up to

24.5” x 24.5”, delivering excellent flatness and uniformity. Suitable for advanced build-up technologies for panel level packaging and SLP including SCHMID “Any Layer ET-Board”, SAP and TGV level as Glasssubrates.

The technology will be a must for sub 5 μm structures in high volume manufacturing.

Depending on the application, a wide range of slurry chemistries can be employed to match specific product need.

Details

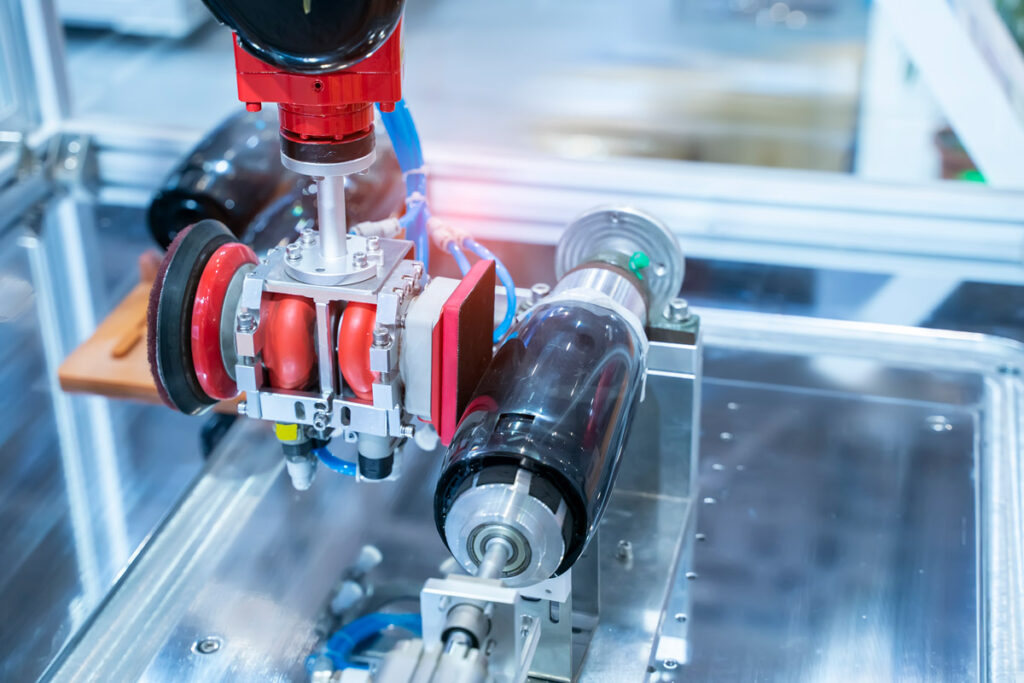

The OSCAR CMP system achieves fastest planarization with minimal dishing across all copper-crystal structures. Combined with SCHMID’s process know-how, it ensures optimal polishing performance with perfect synergy between uniformity and removal rate.

In advanced applications such as embedded traces, HAR via filling, or mSAP/SAP, CMP is the key to high yield and enables the use of new low-Dk epoxy materials.

As part of SCHMID’s embedded trace technology, the CMP system fully supports Industry 4.0 requirements. It offers multiple interfaces to customer MES systems, and the web-based HMI enables operation and control from any device.

Technical data

Head: Ø 930 mm, 30-100 rpm, max. 1450 kg, ±15° swing range @ 0-5 rpm

Platen: Ø 1300 mm, 30-100 rpm with cooling structure

Pumps: 2 slurry pumps for separate slurry supply, 0,980 l/min each

Loading & Unloading: manually, dry-in/wet-out

Conditioner: Swing arm type nylon brush

Control: PLC & Touch Screen

Structure: Simple, robust and high rigidity

High uniformity: NU < 10 %

Repeatability: WTWNU < 7 %

Planarisation factor: ~ 2

Removal rate: ~3μm/min

Dishing: <2μm

Working size: Max. 915 mm (36 inch) Ø

Dimensions: 2600x2700x2500 mm (WxDxH)

Contact

We look forward to getting to know you!

Simply select your region and leave us a message.

EUROPE

CHINA

Tracy Xie

xie.tr@schmid-group.com

TAIWAN

Johnny Tseng

tseng.jo@schmid-group.com

KOREA

Jaho Kim

kim.jh@schmid-group.com

REST OF ASIA

AMERICA