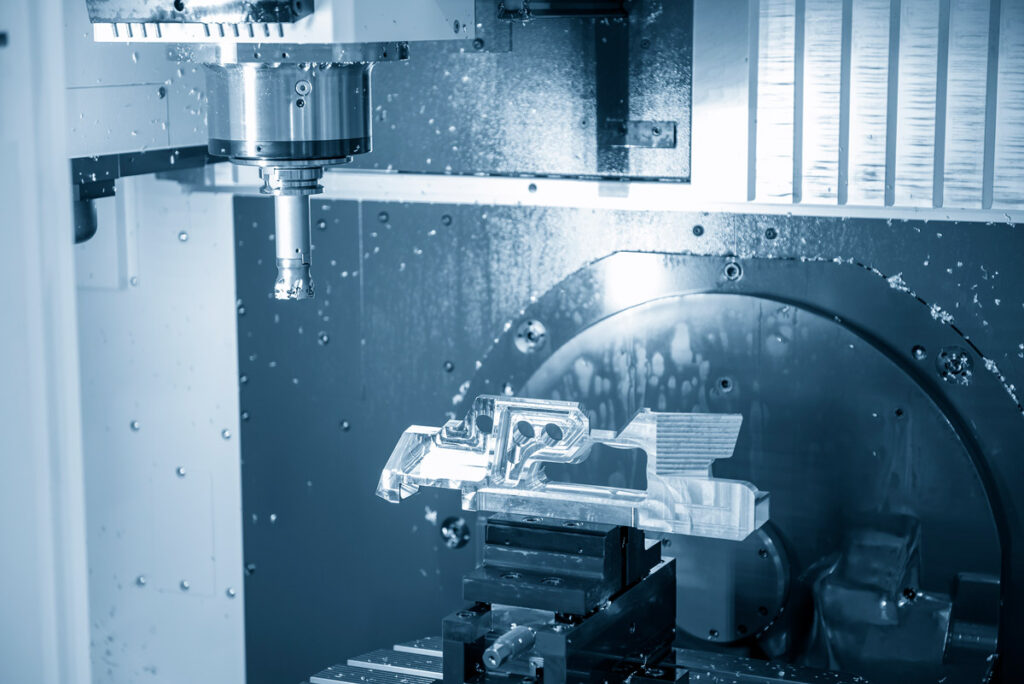

For etching metallic foils and sheets

Since the 90s, SCHMID has collected the required expertise for all types of etching applications. Combined with our high manufacturing standard this forms the basis for the highest quality and precision of our systems – and this at the best price-performance ratio.

Details

Etching is a very important part in the PCM process. For instance, it needs to be considered how metals will be processed and which technical requirements are necessary according to the design and the application of the manufactured product. Furthermore, details as the type of chemicals, line speed, process time or transport system determine the advanced SCHMID etching machine layout. In addition to the etching equipment, SCHMID is also offering equipment for cleaning, developing and stripping.

High etching quality

The fine line spray manifold allows a high etching factor with smaller tolerances. Precise etching results and a uniform spraying pattern are achieved.

Option: individualized module configuration

To create an individual process sequence the etching modules can be combined with modules of the entire line system in a customized configuration.

Additional Options:

- Exhaust condensor system

- Drip pan

- Solution transfer tank for waste water

- Different systems for process control

(pH, redox, density and conductivity sensor etc.)

Technical data

Working width:

- 650 mm

Working temperature:

- max. 68°C

Working height:

- ≥ 900 mm

Conveyor speed:

- 0.01 – 3.0 m/min

- Option: 0.2 – 6.0 m/min

Transport system:

- Standard Transport

- Option: Flex Transport

- Option: Reel-to-Reel Transport

Panel thickness:

- 0.3 – 6.0 mm

- Option: 0.05 mm – 3.2 mm

Panel width:

- max. 650 mm min. 250 mm

- Option: min. 50 mm

Spray manifold:

- 6-fold staggered Oscillation spray manifold

Control system:

- PLC controlled

Dosing system:

- Process control based on various sensors available

Contact

We look forward to getting to know you!

Simply select your region and leave us a message.

EUROPE

CHINA

Tracy Xie

xie.tr@schmid-group.com

TAIWAN

Johnny Tseng

tseng.jo@schmid-group.com

KOREA

Jaho Kim

kim.jh@schmid-group.com

REST OF ASIA

AMERICA