Touch-free plating process

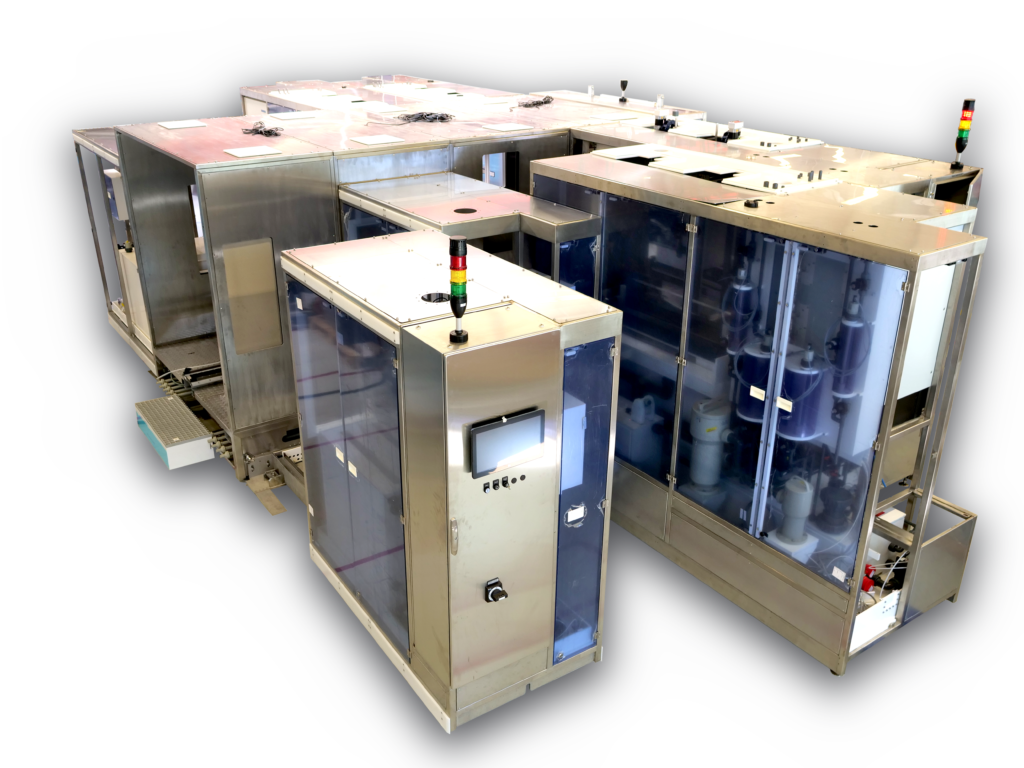

InfinityLine P+ is a touch-free, double side vertical plating cluster tool that can be configurated with several plating chambers combined with special pretreatment, cleaning and rinsing chambers. Each plating chamber is equipped with a pre-acid step, the plating chamber itself and the first pre-rinse step after plating. The plating chamber is equipped with segmented and movable anodes to reach highest plating uniformity. For different plating applications, adjustable shieldings, diaphragma, vertical or laminar parallel electrolyte flow are available. To be able to contact thinnest seedlayers, SCHMID designed a unique water cooled platinated titanium contact. The contacts are sealed to the plating bath therefore maintenance free.

Details

The InfinityLine P+ is a modular vertical touch free plating cluster. The clamping frame to hold the substrate at the edge is the same as used in other SCHMID touch free lines like InfinityLine V+ or C+. This makes it easy to combine different SCHMID touch free machines in one production.

The newly invented water cooled platinated titanium contact is able to contact seed layers down to 500nm. The sealed contacts have no need to be stripped regularly. The segmented anodes allow the control system to compensate the voltage drop over the panel area to get highly uniform plating results. In addition, several useful features like exchangeable shieldings, movable anodes, vertical or parallel electrolyte flow are available.

The InfinityLine P+ supports all requirements for industry 4.0. Different interfaces to customers MES are available. The web-based HMI allows to run and control the system from different devices.

Technical data

General Information

- Substrate dimensions: 0,025 mm – 3,0 mm

- Minimum: 12” x 24” (457 x 610 mm)

- Maximum: 24” x 24” (610 x 610 mm)

- SCHMID Clamping frame required

- Max. throughput 2 panels/min.

Process Chamber:

- Eight independently controlled rectifier outputs, each up to 100A forward / 240A reverse

- Each output has programmable and synchronized waveforms

- DC

- Reverse pulse

- Complex wave

- programmable

- High accuracy in current control <1%

mismatch for maximal plating control - Watercooled and sealed cathodic contacts – maintenance free

- Preacid dip and first rinsing step after plating included in process chamber

- Separate pre-clean and rinse-/dry chambers are available

Contact

We look forward to getting to know you!

Simply select your region and leave us a message.

EUROPE

CHINA

Tracy Xie

xie.tr@schmid-group.com

TAIWAN

Johnny Tseng

tseng.jo@schmid-group.com

KOREA

Jaho Kim

kim.jh@schmid-group.com

REST OF ASIA

AMERICA